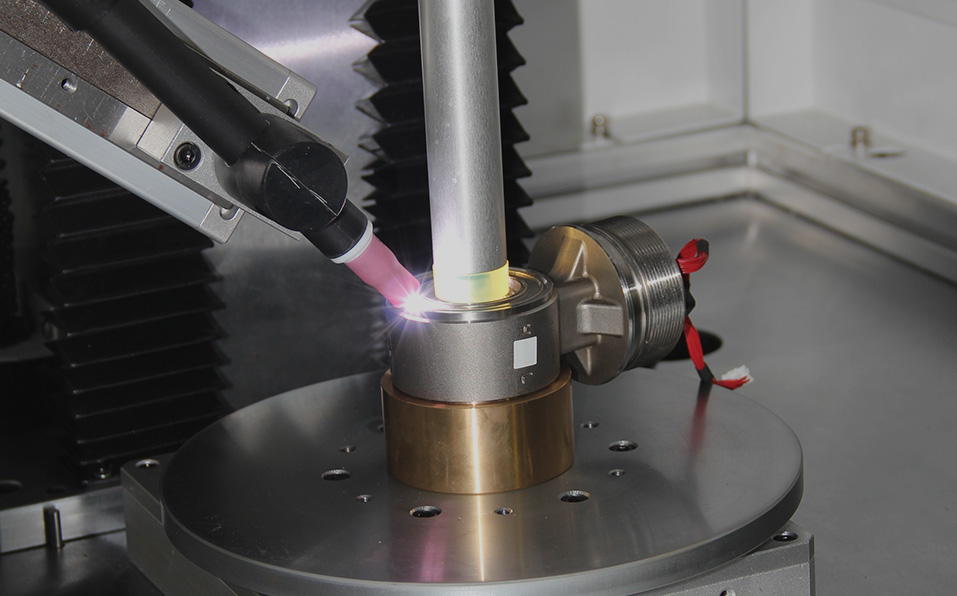

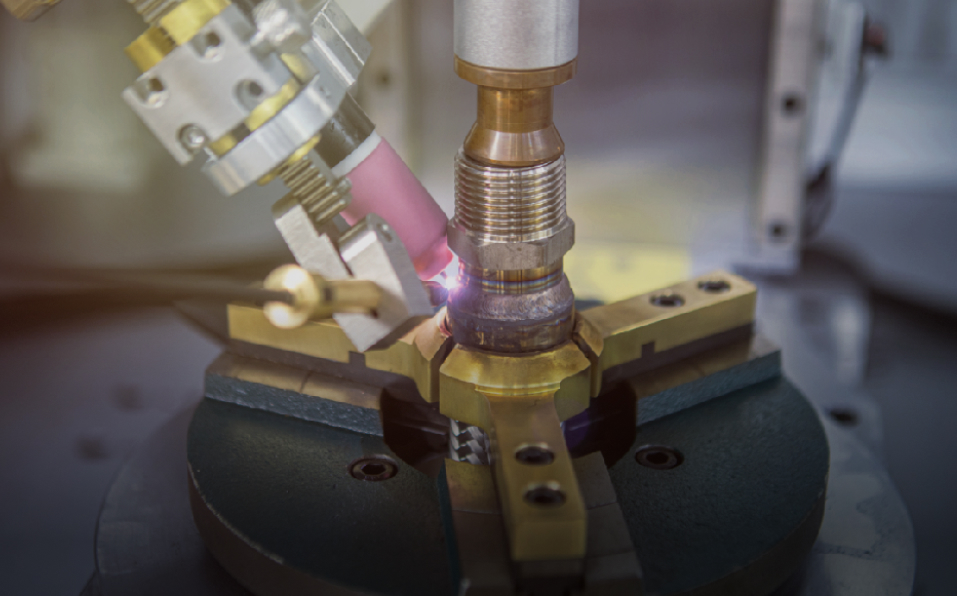

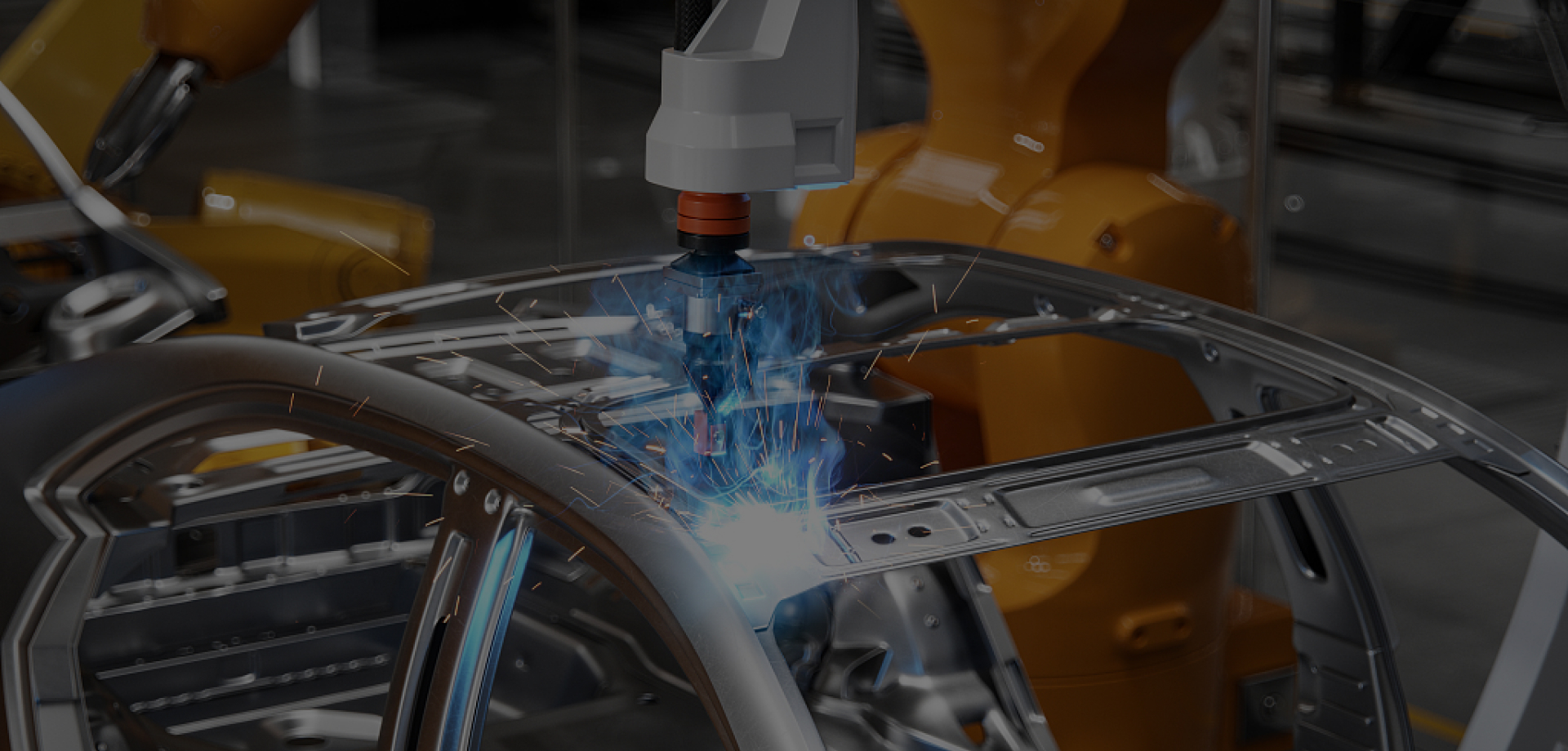

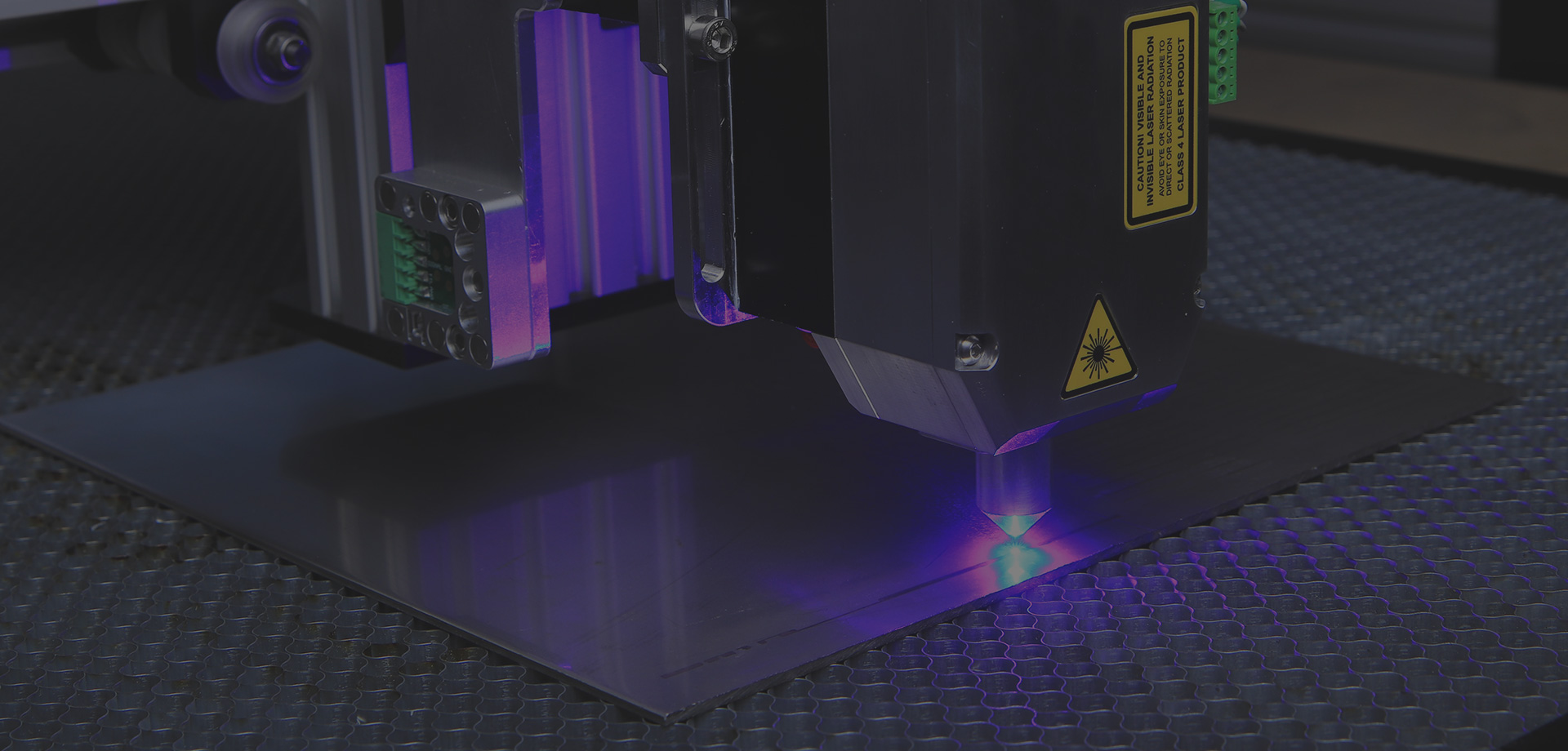

We provide total solutions for automated welding of diaphragms, valve bodies, housings, fittings and flanges for instrumentation type temperature, level, flow and pressure sensors, etc.

- Home

- HI-MACH

-

Automatic welding machine

- Instrument type automatic welding machine series

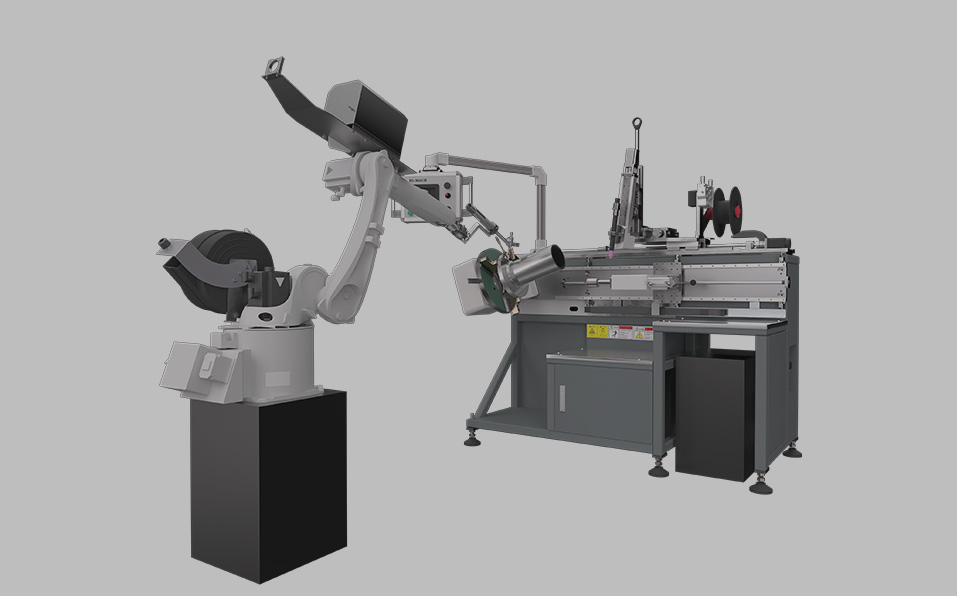

- HI-MACH 06SAutomatic Welding Machine for small tubes and joints

- HI-ARC 15C SERIESCurved-tube Automatic Welding Machine

- ACU-ARC/BDiaphragm Automatic Welding Machine

- ACU-ARC/RMulti-functional Automatic Welding Machine

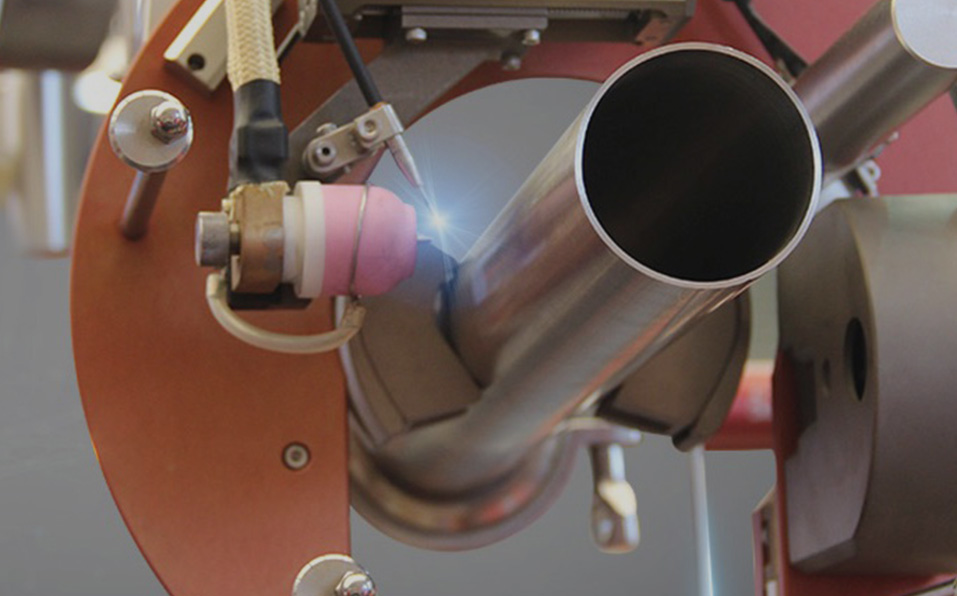

- MICRO-ARCMicro-beam Automatic Welding Machine

- ROBUST-ARC TCAutomatic Cutting and Welding Machine

- Hose/Hose Automatic Welding Series

- HI-CUT 10/35Bellow Weld Joint Cutting and Leveling Machine

- ROBUST-ARC 06/35Automatic Welding Machine for Bellows Joint

- MICRO-ARC 10LAutomatic Welding Machine for Elastic Element

- MICRO-ARC 10HDiaphragm Bellows Automatic Welding Machine

- ACU-ARC 10/15Hose Automatic Welding Machine

- LT760Welding Workbench

- Solutions

- Application

- Service

- Information

- Contact